Budnick Converting

Custom Manufacturer

•Columbia, IL 62236![]() •More... Visit WebsiteSave SupplierAdd To Shortlist

•More... Visit WebsiteSave SupplierAdd To Shortlist

Request Information Visit Website • 888-297-9654 Call Supplier

Transaction Assurance Available

Protects your purchases for 21 days after the delivery date or intended delivery date. Learn MoreBusiness Description

- Pressure Sensitive Tapes Details

- |

- About Budnick Converting

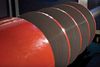

Distributor of unsupported and single/double-coated pressure sensitive tapes. Capabilities include converting, precision cutting, die-cutting, slitting, printing, adhesive coating, finishing/spooling, consulting, prototyping and inventory management. Used in high temperature gasketing, nameplate, faceplate and membrane switch fabrication applications. Serves the aerospace, appliance, automotive, building supply, distribution, electronic, energy, oil and gas, marine, medical, moving and storage, signage, printing and transportation industries.

Company Description by Thomasnet

Budnick Converting, Inc. engages in the sale and conversion of adhesive tapes and foams. Our primary converting services include slitting, die-cutting, printing, spooling, adhesive coating, laminating, xyz axis table-top cutting, waterjet and in-line laser cutting services. Budnick offers services for various industries, including appliance, automotive, building materials, electronics, transportation, moving and storage, medical, point of purchase/signage/printing and distribution. Budnick Converting, Inc. is a woman owned enterprise. The company was founded in 1952 and is based in Columbia, Illinois, near St. Louis, MO. The company has sales, distribution or converting locations in St. Louis, Kansas City, Dallas, Chattanooga, Oklahoma City, Atlanta and Tampa. It also has a joint venture converting company in Monterrey, Mexico.

Company Description by Budnick Converting

Budnick Converting, Inc. is a custom converter and distributor or adhesive tapes, foams, and other flexible materials. The company's primary converting services include slitting, die-cutting, printing, spooling, adhesive coating, laminating, high speed plotter, and waterjet and in-line laser cutting services. Budnick offers services for various industries, including appliance, automotive, medical, electronics, building supply, POP/signage/printing, truck and trailer, moving and storage, aerospace, and distribution. Budnick Converting, Inc. is a Woman's Owned Enterprise. The company was founded in 1952 and is based in Columbia, Illinois, near St. Louis, MO. The company has sales, distribution or converting locations in St. Louis, Kansas City, Charlotte, Dallas, Atlanta and Tampa. It also has a joint venture converting company in Monterrey, Mexico.

Products / Services Offered

Tapes

Pressure Sensitive Tapes Brands Carried

- 3M

- American Biltrite

- Avery Dennison

- Berry

- EconOtape

- Gaska

- Intertape

- Nitto Denko

- Permacel

- Saint-Gobain

All Brands Carried

- 3M

- American Biltrite

- Avery Dennison

- Berry

- DeWal

- EconOtape

- Gaska

- Intertape

- MacTac

- Nitto Denko

- Permacel

- Saint-Gobain

- Shurtape

- Specialty Tapes

- TaraTape

- TESA

Business Details

- Custom Manufacturer

- Distributor, Manufacturer, Service Company, Finishing Service Company

- Ann Wegmann, Owner

- Gary Smith, Marketing Manager

- Zach Heller, Digital Marketer

Diverse / Small Bus. Status

- Minority Owned ?

- Small / Disadv. / HBZN ?

- Woman Owned ?

- Veteran Owned ?

Certifications / Registrations

- $25 - 49.9 Mil

- 100-199

- 1952

Thomas Verified Supplier

The Thomas Verified Supplier badge indicates that Thomas has confirmed the company operates in North America, provides accurate business information on the Thomasnet.com supplier discovery platform, has undergone a complete review and validation of all products and services currently offered, and are open to quoting new opportunities.

Pressure Sensitive Tapes Products & Capabilities

Pressure Sensitive Tapes Portfolios

View Items

View Items

View Items

View Items

View Items

View Items

View Items

View Items

Additional Information Provided by Budnick Converting

Capabilities / Services

News & Press Releases